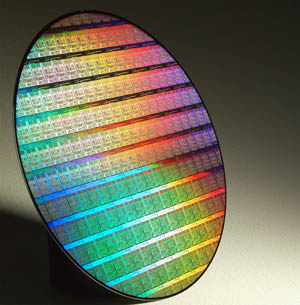

"We evaluated various MES products for our semiconductor packaging applications and found that many were not able to satisfy our needs for both full-wafer and chiplet processing in tandem. However, because of the flexibility and ease of customization with ToolTrack, we got a system that fully enabled our unique process capabilities. Furthermore, it was a pleasure to work with the Chain Reaction Systems (CRS) team who were very responsive to our requests and readily accommodated them into the application. Kudos to CRS for the fabulous collaboration and customized MES."

"We chose ToolTrack MES to replace our paper travelers because many of the standard features matched what we needed, at a price point that fit our company's budget. The support team is exceptionally responsive, and their experience as engineers who have been users of other MES is evident in the way the system architecture is able to adapt to unique processing requirements. Customization work was completed quickly, and came with detailed instructions, including screen captures and examples on dummy lots as explanation aids."

"NexGen is a GaN-on-GaN semiconductor manufacturer running ToolTrack MES for our Fab operations. ToolTrack has been exceptionally reliable and an excellent fit for our production team. Its flexibility has allowed it to become immersed in our processes and become what we rely upon to 'run the business'. I cannot speak highly enough of the responsiveness and energy the Chain Reaction Systems team offers us. They not only provide in-depth knowledge on ToolTrack, but great insights as to what MES modeling decisions work best for our environment. These insights have been invaluable as we integrate ToolTrack to other systems (analytics, ERP, etc.) I am a strong proponent of ToolTrack and the entire CRS team."

"The most important part of MES software is the team supporting it. Chain Reaction Systems has an excellent team. They are highly customer focused, readily available, honest when they cannot accommodate a request and helpful coming up with alternative solutions. Equally important is the ability of an MES to handle a semiconductor process flow, and CRS has that experience. We vetted other MES products; for systems in a similar price range, we could not fit our process into their rigid box. ToolTrack MES is flexible and well organized, which allows quick responses to change requests and the ability to match as closely as possible our existing process flow. My company has been running on excel macros for years, but with the help of ToolTrack we are automating our data to reduce error, improving data visualization with in-app charts and customizable reporting, and getting data to engineers quicker. The Chain Reaction Systems team developed new API endpoints to accept our specific data types, customized ToolTrack MES to our process flow, and helped us build and guide our team to drive automation within the MES. Great team, great product. I highly recommend Chain Reaction Systems and ToolTrack."

"We implemented ToolTrack MES in our company about two years ago. The company was moving from Excel based travelers to an MES and needed one with flexibility and ease of use. We found that in ToolTrack and partnering up with Chain Reaction Systems (CRS) was the best decision. The CRS team was there to help guide us every step of the way. ToolTrack is very user friendly and easy to navigate for all users, from the administrative back-end to the users on the floor. Our management team and board of directors were thrilled with the reporting that the system easily generates. If your company is looking for an MES, partnering with the team at Chain Reaction Systems is a decision you will be glad you made. ToolTrack is not priced like the big companies, ToolTrack MES gives you the power of the big companies."

"We analyzed several options for a quality system and quickly landed on ToolTrack because Chain Reaction Systems was able to customize to our specific needs at a fraction of the cost of other systems investigated. ToolTrack has enabled us to implement a fully functional MES, QMS, and EMS from scratch. The team at Chain Reaction Systems has been responsive to our specific needs and provided fast customer service when needed."

"As our manufacturing capability grew, we required an MES to help track the various process flows and products within the manufacturing line. The Chain Reaction Systems Software solution, ToolTrack, is not just very cost effective but is also extremely adaptable. Requests for additional features is always acknowledged with a positive attitude and rolled out in a timely manner."

"It's amazing what we have accomplished with ToolTrack in a short time. We signed the contract, and 45 days later we had implemented an active LIMS system... it was so easy to do! We were in a production ramp, so even though ToolTrack was being implemented it was not our company's main focus. After two weeks of using the system the staff provided feedback that they couldn't believe the implementation went so well without causing a big disruption, and that ToolTrack was really helping them. ToolTrack has the flexibility that a growing company needs, and Chain Reaction Systems provides complete support during the entire project. I strongly recommend ToolTrack, and the people behind it."

"ToolTrack checks all the boxes: full functionality; easily configurable to fit our specific needs; scalable, secure architecture; fast implementation; sensible pricing model; all backed up by a great responsive team."

"Our internal selection team looked at many MES solutions, and after an exhaustive search process, we decided to go with the Chain Reaction Systems team and their ToolTrack Platform. ToolTrack “off the shelf” version had many of the features called out in our functional spec and the process of customizing the remaining portions was remarkably easy and efficient. As a fast-moving R&D organization, we needed a product which could adapt to our needs with the cycle time to implement changes at an absolute minimum. Chain Reaction Systems delivered every time and we are very pleased with the results."

"We were in the market for an MES for document control, consumable traceability, statistical process control, and reporting. ToolTrack delivered on all of these aspects and more. I have found that ToolTrack is very powerful with many added features that will come in handy as our company grows. Pros: ease of use, great customer service, easy customization, low cost."

"Incredible customer support! They strive to respond within a day for small requests. For larger issues, such as adding features and customizing reports, they have been incredibly responsive."

"I've used multiple MES Platforms for microelectronics manufacturing and R&D applications as an Engineer. I’ve also evaluated several for purchase... ToolTrack takes the cake for being the best I’ve used, even over the ones costing orders of magnitude more. ToolTrack Has the rare duality of being flexible enough for R&D tracking, yet still user friendly on the manufacturing floor. Scalability is another strong point - for a startup or small business, ToolTrack serves as a capable and cost-friendly system which can easily scale as your company grows. Finally, the support is fantastic! The folks at Chain Reaction Systems have years of experience in high volume manufacturing and R&D environments, and are eager to help solve your problems. And they are pleasant (even fun!) to work with."

"Chain Reaction Systems has done a fantastic job of building a system that is very easy to use and manage."